Fight COVID-19 with Copper, Brass, Bronze

FIGHT COVID-19! GET A QUOTE ON A COPPER, BRASS, OR BRONZE COUNTERTOP AND SINK TODAY!

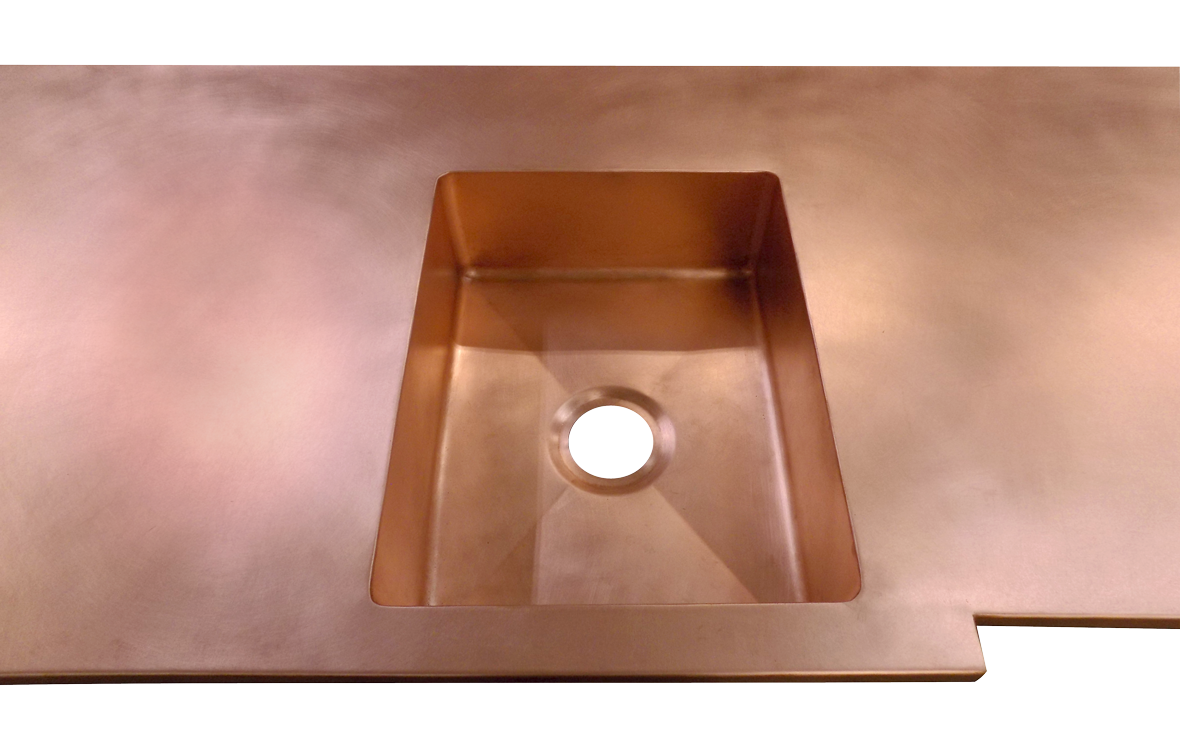

Fight COVID-19 and other dangerous pathogens with a copper or copper based alloy countertop and sink, where germs and viruses are likely to gather and linger. It is well documented that copper and copper alloys such as brass and bronze kill viruses and microbes on contact. This natural ability to fight pathogens means that unsealed surfaces are self-disinfecting and will destroy COVID-19, as well as other viruses including stomach illness producing noroviruses and bacteria. These properties have been put to use since ancient times, though the scientific reasons for its efficacy have only come to light much more recently. Here are some quotes from the American Society of Microbiology addressing some of copper’s amazing properties:

Copper countertop with integrated sink. Copper is known to kill microbes and viruses such as coronavirus and more. Get a quote on a custom sink or countertop today!

- “Rapid inactivation of human coronavirus occurs on brass and copper nickel surfaces at room temperature (21°C).”

- “…noroviruses are destroyed on copper alloy surfaces.”

- “…copper alloy surfaces could be employed in communal areas and at any mass gatherings to help reduce transmission of respiratory viruses from contaminated surfaces and protect the public health.”

- “…highly infectious nonenveloped viruses that are resistant to environmental stress and impervious to many cleaning agents, are destroyed on copper and copper alloy surfaces”

- “Copper alloys have demonstrated excellent antibacterial and antifungal activity against a range of pathogens in laboratory studies.”

- “In this new study, human coronavirus 229E was rapidly inactivated on a range of copper alloys (within a few minutes for simulated fingertip contamination) and Cu/Zn brasses were very effective at lower copper concentration.”

Source: Human Coronavirus 229E Remains Infectious on Common Touch Surface Materials

Sarah L. Warnes, Zoë R. Little, C. William Keevil

mBio Nov 2015, 6 (6) e01697-15; DOI: 10.1128/mBio.01697-15

Copper countertop with integrated sink. Copper is known to kill microbes and viruses such as coronavirus and more. Get a quote on a custom sink or countertop today!

Repoussé

This month’s blog topic is the on the art of Repoussé.

Repoussé is an ancient skill used in metal craft to create beautiful images in malleable metals. The term Repoussé is derived from the French word pousser, “to push forward.” The techniques of Repoussé are found worldwide from ancient times, such as the gold mummy mask of Tutankhamun, to today, as demonstrated in the Statue of Liberty.

The repoussé design is created by raising the image from the back using special hammers and chasing fine details from the front. Bas-relief (low relief) repoussé is often confused with a mass production process of “rolling” or “stamping” designs into metal with special forming machines. This kind of imprinting a design into metal does not typically result in the fine detail associated with genuine repoussé, and doesn’t allow for cost-effective intricate one-off custom designs.

Texas Lightsmith artisans are skilled in this venerable process to create unique one of a kind functional art products. Watch the video for inspiration on how to incorporate repoussé into your Texas Lightsmith project.

What is the Living Finish?

The living finish in this Farmhouse Sink – in its home in High Falls NY.

Medium Copper; Hard Distressed Apron; Custom Sink Grate

More examples of the Living Finish can be seen on our web site.

A living finish is often a much sought-after look when buying a copper, brass, bronze or nickel silver sink. Without an added protective coating, these materials are allowed to age gracefully in their natural state in what is referred to as the living finish. Over time, the finish will oxidize with use, adding more character and uniqueness to your custom piece.

The term “living finish” comes up most often regarding copper sinks. Faucet and drain manufacturers generally address this issue with coatings that protect the metal surface from environmental factors preventing the patina or oxidation of the finish. However, these coatings (PVD, powder coating and others) are more difficult to apply to a larger surface area such as that of a sink and require a mass production manufacturing process. In effect many of the artisan crafted copper, brass, nickel silver and bronze sinks are not sealed and will have a true living finish.

Stainless steel products are often referred to as “non-living”. However the surfaces of these products can also dull over time depending on the environmental factors involved and how well they are cared for. Nickel is also occasionally referred to as “non-living finish,” though nickel will patina or “tarnish” as well.

With uncoated brass, nickel silver, bronze, and copper the patina or oxidation process occurs more rapidly. So, what happens to the metal finish over time? The answer depends your finish choice and how the patina is applied when the sink is made, the environmental factors involved in your home, how much it is used and the type of care and maintenance you have decided to go with.

If you choose a copper sink that has a medium, dark or oil-rubbed finish; heat and/or chemicals have been applied to speed up and mimic the aging process. In creating these finishes, the metal has likely been exposed to a chemical bath and or heat causing a reaction with the metal and changing its color. In choosing a medium, dark, or oil-rubbed finish you still have a living finish that will evolve. However, the darker the patina is to start with, generally the slower the changes are over time.

Environmental factors specific to your home and chemicals that may be exposed to the surface of your sink are the great unknown. Every finish application and environment is different. Some factors include but are certainly not limited to;

- Humidity

- Airborne salinity

- Pollutants

- Oxygen content

- Foods

- Cleaning products and other household chemicals

- Water hardness

All the elements and conditions listed above and more will work together with time to coat the metal surface with a unique patina. If you have a copper sink and expose the metal surface to certain acids such as those found in lemon juice, you will actually dissolve some of the patina. The constant changes due to limitless factors are admired by some and not so admired by others. You can anticipate your product to have its own “character” and appreciate the uniqueness in color and tone between two identical products in different environments.

If you admire a living finish, the care and maintenance will be fairly simple. If you wish to mitigate it, this is often possible to a certain extent. There are several different ways you can slow down the patina process. Applying a special wax that does not contain polish or cleaners (such as beeswax) can slow the change in patina similar to how an automotive wax protects the finish of your car. Patina on a sink can be removed with a metal polish or mild acid such as lemon juice or vinegar. Waxing the surface can preserve the shine, or you can leave the newly untreated metal to develop a new patina, how exciting!.

Some customers are fearful that the living finish will be more maintenance or it will turn out undesirable. Any copper or brass cleaner will revert the patina back to a bare surface if you so desire. Left unprotected, the aging process starts over again and within a few weeks the metal surface will begin to darken. In opposition, you could choose a sink with a darker finish and wax the surface regularly ensuring the least amount of change over time. While these methods will help mitigate or retard the evolution of your sink’s patina, the living finish phenomenon will still continue.

An occasional cleaning with soap and water is the recommended maintenance. If you choose to wax your sink to extend the life of the desired finish, it is generally something you will need to do approximately every 3 – 6 months depending on the frequency of use.